Supply chain management entails supervising the complete production flow of goods or services, starting from raw components to the end delivery. It establishes networks of suppliers to facilitate product movement and delivery to end consumers. Effective supply chain management minimizes costs, waste, and time, optimizing the production cycle.

Analyzing partner data enhances value by identifying problems, optimizing pricing, and improving inventory allocation.

Planning, sourcing, manufacturing, delivery, and returns make up the base elements of any working supply chain. Each stage involves meticulous coordination and management to ensure seamless operations.

An effective SCM is interconnected, collaborative with 'n'number of moving variables, socially and ethically conscious, aware of online trends, adaptive and intuitive, and highly comprehensive of the top-to-bottom management cycle.

Modern SCM focuses on data management, services, and product solutions, optimizing efficiency and profitability. Supply chain consulting and leveraging technologies like AI and blockchain enables responsive, innovative workflows.

Evolution of supply chain management

Modern supply chains focus on data, services, and solutions rather than just physical assets. They leverage advanced technologies like AI, analytics, and blockchain to optimize processes, improve customer experience, and drive profitability.

Leveraging data analysis for improvement

Analyzing partner data helps anticipate potential problems, optimize pricing dynamically, and improve inventory allocation. Data-driven insights enable proactive decision-making and enhance supply chain performance.

Key features of effective supply chain management

Effective supply chain management is characterized by connectivity, collaboration, cyber awareness, cognitive enablement, and comprehensiveness. These features enable agile and responsive supply chain operations, enhancing overall efficiency and performance.

Significance of effective SCM for procurement operations

Effective SCM is crucial for procurement operations as it streamlines processes, reduces costs, and enhances overall efficiency.

By optimizing the supply chain, procurement companies can minimize inventory holding costs, mitigate risks associated with disruptions, and improve supplier relationships.

Additionally, efficient SCM enables better inventory management, faster order processing, and improved customer satisfaction, ultimately contributing to the company's bottom line.

Supply chain management components in detail

Resource planning: Managing resources to meet customer demand efficiently. Metrics are established to ensure effectiveness, value delivery, and align with company goals.

Supplier selection and management: Choosing suppliers for goods and services required for product creation. Processes include ordering, receiving, inventory management, and payments.

Production organization: Activities from raw material acceptance to product manufacturing, quality testing, packaging, and delivery scheduling.

Distribution and logistics coordination: Coordinating customer orders, scheduling deliveries, dispatching loads, invoicing, and receiving payments.

Product returns management: Processes for handling defective, excess, or unwanted products.

Effective supply chain management enhances a business's reputation and long-term sustainability by serving as the primary interface between customers and consumers.

SCM in procurement companies comprises systematic planning, coordination, and optimization of processes involved in sourcing, procurement, production, and distribution. It encompasses the entire lifecycle of goods or services, from acquisition to delivery, aiming to ensure efficiency, cost-effectiveness, and timely delivery.

Key challenges in supply chain management

Challenges include inefficient communication channels, difficulty in tracking and managing support requests, and disjointed processes leading to prolonged resolution times. These obstacles impact business operations and customer satisfaction.

Common challenges in SCM for procurement companies include supplier management issues, inventory management complexities, demand forecasting inaccuracies, and supply chain disruptions.

Other challenges may include inefficient processes, lack of visibility across the supply chain, and compliance issues with regulations and standards.

Impact of these challenges on procurement business operations and outcomes

These challenges significantly impact business operations and outcomes, leading to increased costs, delayed deliveries, decreased customer satisfaction, and lost revenue opportunities.

Poor supplier relationships and communication breakdowns can result in quality issues or supply shortages, affecting product availability and brand reputation. Moreover, supply chain disruptions, such as natural disasters or geopolitical events, can disrupt operations and cause financial losses if not adequately managed.

Leveraging BPM for enhanced SCM efficiency

Business process management (BPM) offers a systematic approach to addressing SCM challenges by streamlining workflows, automating repetitive tasks, and improving collaboration among stakeholders.

BPM enables process standardization, visibility, and control, allowing procurement companies to identify inefficiencies and optimize operations.

BPM plays a crucial role in optimizing procurement processes for efficiency by providing real-time insights, monitoring key performance indicators (KPIs), and facilitating continuous improvement.

With BPM, procurement companies can enhance transparency, agility, threshold in scaling SCM, and responsiveness across the supply chain, resulting in cost savings, reduced cycle times, and better decision-making.

Implementing BPM solutions in procurement companies

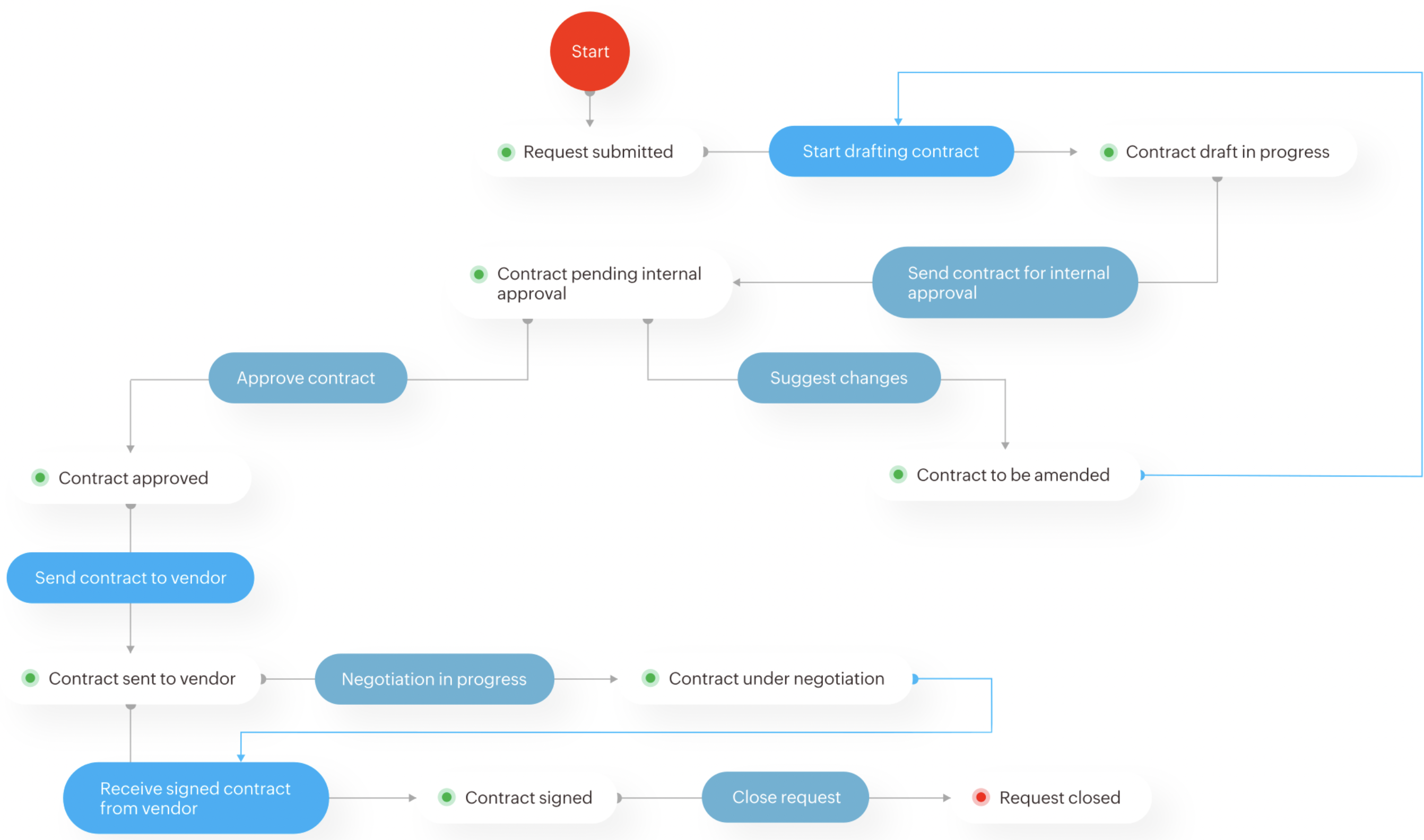

BPM solutions can alleviate SCM pain points in various areas, including supplier management, inventory control, order processing, and contract management.

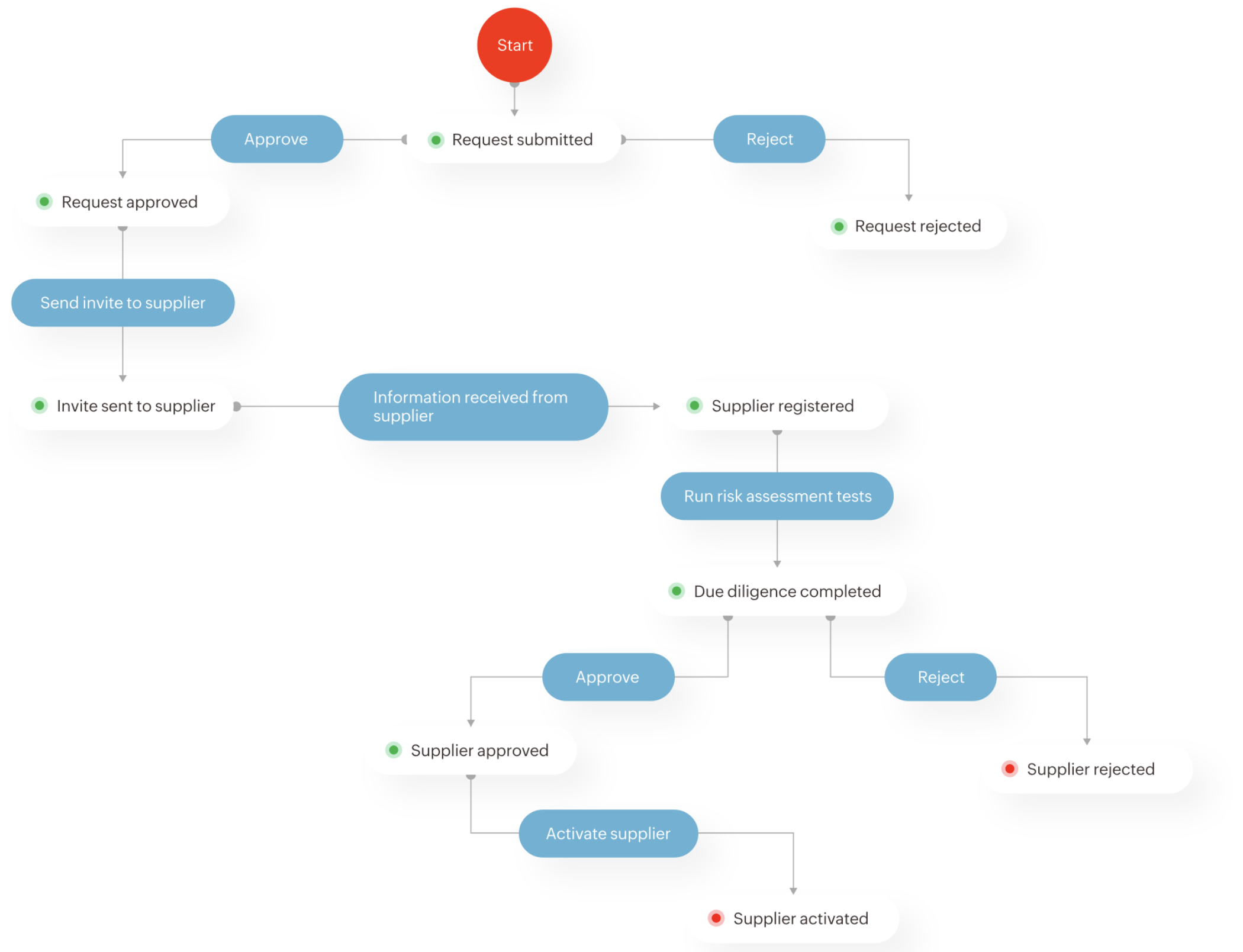

By implementing BPM tools, procurement companies can improve vendor onboarding processes, streamline purchase requisition workflows, and enhance demand forecasting accuracy.

Practical examples of BPM tools tailored for procurement include workflow automation platforms, supply chain visibility software, and contract lifecycle management systems.

These solutions offer features such as customizable workflows, real-time analytics, and integration capabilities with existing procurement systems, empowering companies to optimize SCM processes and drive business growth.

Strategies for overcoming SCM challenges with BPM

Implementing BPM in SCM requires careful planning and execution. Start by conducting a thorough assessment of current SCM processes to identify areas for improvement.

Collaborate with cross-functional teams to define clear objectives and goals for BPM implementation. Invest in training and change the handling of management initiatives to ensure buy-in from stakeholders and a smooth transition.

Leverage BPM tools to automate routine tasks, streamline communication, and track performance metrics for continuous optimization.

Addressing unique pain points in procurement SCM involves tailoring BPM strategies to specific challenges.

For instance, if vendor management poses a significant challenge, concentrate on integrating BPM workflows for demand forecasting, vendor optimization, and supply replenishment.

Work closely with suppliers to establish data-sharing mechanisms and streamline procurement processes.

Emphasize the importance of flexibility and scalability in BPM solutions to adapt to changing business requirements and market conditions.

Regularly evaluate and adjust BPM strategies to align with changing SCM requirements and industry trends.

In conclusion, leveraging BPM solutions is crucial for procurement companies to optimize their operations, reduce costs, and enhance customer satisfaction. By addressing SCM challenges with BPM, organizations can streamline workflows, improve transparency, and drive efficiency across the supply chain.

Implementing tailored BPM tools enables companies to overcome obstacles and achieve sustained growth in today's competitive landscape.